PROS

- Energy usable almost completely

- Charging speed

- Low weight (10,5 kg!)

- It resists very well to high absorption

CONS

- High price

- There is no indication of the state of charge

November 23, 2021 – It was a difficult summer for us, believe it. Having had to suspend our “journey” and return to stay within four walls was certainly not what we wanted, even if it was necessary, and now we have reopened the planning phase for a next restart, which we are imagining at the beginning of the new year. In this context, we have found ourselves to be more “normal” motorhome owners, who use the vehicle more occasionally and sporadically. Our collaboration with the companies that are giving us their support has therefore forcibly slowed down, because we have not had the opportunity to “whip up” their products as we would have liked.

However, the impressions of use of these last two months are those of who use the recreational vehicle on the weekend or in extended journeys of a few days, and therefore can be useful to those who are considering a particular solution such as that of lithium batteries. The lithium yes/lithium no debate is particularly heated, and therefore it is worth leaving aside the various parochialisms and trying to understand if this is a solution only for a fulltimer, or even for a user who makes a massive use of the motorhome, or if it is also recommended for weekend tourists and for one or two holidays a year.

The first vehicles with lithium features

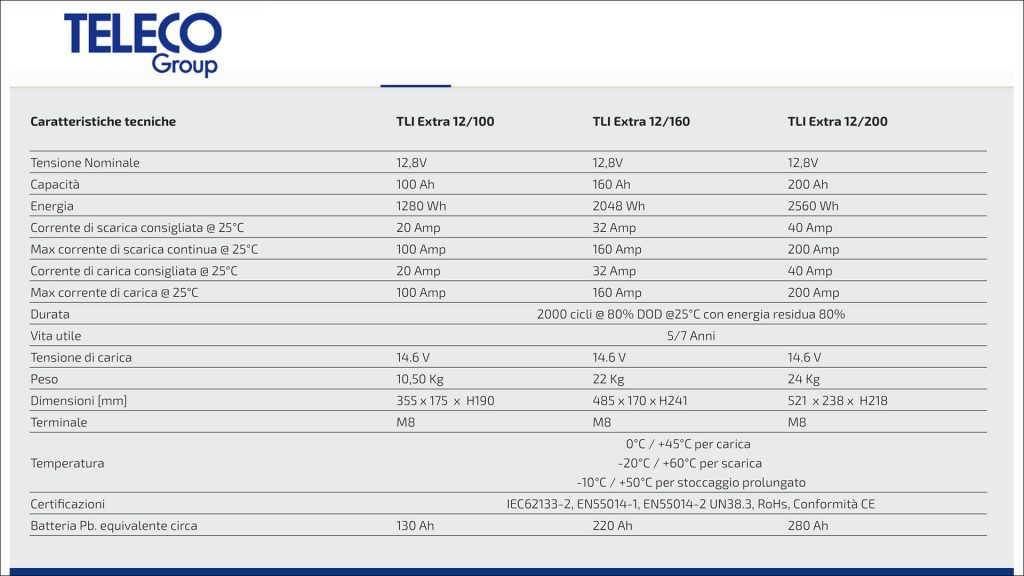

As you know, we have installed a lithium battery since last April, based (like all those designed for recreational vehicles) on lithium-iron-phosphate (LiFePO4) technology, made by Teleco. This is the 12 Volt 100Ah TLI Extra, a product that this year has been installed as standard on various recreational vehicles, starting with the Font Vendôme camper vans. And this is an important signal for the industry, because it shows that this type of product makes sense to use it widely, regardless of specific needs that have prompted its adoption in the past.

LiFePO4 are not dangerous!

We will soon see what the advantages and limitations of lithium batteries are, but first it is better to make a clarification, necessary to dispel the myth of their danger: on social networks, in fact, it is not uncommon to come across users who consider these accumulators dangerous “fire bombs”. This is a perception that derives from what we see in the world of small electronic devices, where for example smartphones have caused various problems in the past due to defective batteries, or in the world of cars, where the danger of fire linked to road accidents it is very high.

However, the concern arises from a basic misunderstanding: lithium batteries are not all the same and those used in telephones and cars are almost always based on a different technology from those found on a motorhome or caravan. Lithium ions, unstable by nature, need to find the right balance and LiFePO4 batteries have an important advantage over other chemicals: much higher thermal and chemical stability, because the cathode material used is inherently safer.

The costs must be analyzed well

Having clarified this aspect, the main criticism normally focuses on the purchase costs, certainly higher than those of lead AGM or Gel batteries. However, the advantages are many, and in some cases lithium batteries can even become cheaper. Let’s see why, taking as a term of comparison one of the most widespread and well-known AGM products on the Italian market and the related suggested sale price to the public. As we know, these “price lists” can then be very different from retailers, depending on the discount applied, so do not be afraid for such high values. Obviously cheaper products can be found on the market for both technologies, but to make a comparison it is necessary that the quality level is similar.

The Teleco TLI Extra is offered on the Italian market for around €1,230 euros, compared to around €270 for the more “traditional” battery: a difference more or less equal to 4.5 times. Here the life of the accumulator comes into play, which can be spannometrically defined in years of use, but more precisely in charging cycles. In the first case it can be argued that the lithium battery will have a useful life ranging from 10 to 20 years, often similar to that of the vehicle itself (or at least of the years in which you remains in possession), while the lead-acid battery will have to be changed with a frequency ranging from 3 to 5 years.

The importance of charging cycles

To better understand this statement, it is necessary to refer to the charging cycles, which are actually tested in the laboratory also by the accumulator manufacturers. A recharge cycle is calculated starting from a battery at 100% of its capacity, discharged to its maximum potential and then recharged. This obviously does not happen in everyday life, but it is a useful objective data for the comparison between different technologies.

Research and development figures say that the charge cycles for an AGM battery range from 500 to 1,000, while those of a lithium battery range from 2,000 to 4,000. Basically, there is a ratio of 1: 4, which means that the duration of a lithium system is on average four times higher. To this it must be added that speaking of discharge, an AGM battery should never drop below 70% (i.e. always maintain a residual charge of at least 30%, under penalty of a decay in the number of recharge cycles), while the lithium battery can be over 90% downloaded and occasionally even 100%. Hence a substantial cost parity between the two technologies.

The advantages of lithium technology

Obviously, there are those who prefer (and can) make a single initial investment and those who believe that it is better to dilute the expense over time. What makes the real difference, however, is the use made of accumulators, because those based on lithium guarantee various advantages, which for some users can prove to be decisive.

MORE ENERGY – We have already mentioned the first, and it is the possibility of using a greater amount of energy before having to recharge. Of a 100Ah AGM battery in safe conditions we can take a maximum of 70 (but we must know that here we are really at the limit to safeguard the health of the accumulator, so much so that many advise not to go below 50/60%), while in the in the case of lithium, it can even reach 100Ah: a difference that is at least 42% more.

MORE STRENGTH – The second advantage is that the lithium-ion battery can withstand much higher absorption without going into crisis. If we connect a device with particularly high consumption, or even just an important starting point, the lead-acid battery makes much more effort, so much so that it often sends the inverters that are unable to take all the energy they would need in a specific instant into protection. An example is that of the espresso machine, even if it does not always occur: a lot depends on the quality of the inverter, the absorption of the machine, its starting point, and the efficiency of the battery.

MORE SPEED – The third point in favor of lithium is its speed of charge. While a lead-acid battery needs to receive current in a fairly slow but constant way, in order to allow the chemical reactions to take place correctly, lithiums are capable of receiving all the current that we are able to offer them at that moment, taking into account only that in the recharging of the last 20% of capacity it is better to lower the quantity, slowing down the charge (which will in any case be faster than with lead).

2/3 hours may be enough for a full charge

Typically, it takes several hours to fully recharge an AGM: the maximum recommended current for a 100Ah is in fact between 15 and 25 amperes, but in the completion phase, recharging becomes very slow. In lithium batteries it is also possible to use higher values, even if after 80% it must drop substantially. Despite this, in two / three hours the recharge can take place from 0 to 100 percent. In real life, if you have a good alternator (and are equipped with a DC/DC converter, as we will see later), you just need to have the engine running for half an hour to recover a good amount of energy. A final element that affects the charging speed is the efficiency of the accumulator: with Gel or AGM ones the value is between 85 and 90%, which means that for a (theoretical) recovery of 100Ah it would take between 110 and 115Ah; with LiFePO4 technology, efficiency reaches 97%.

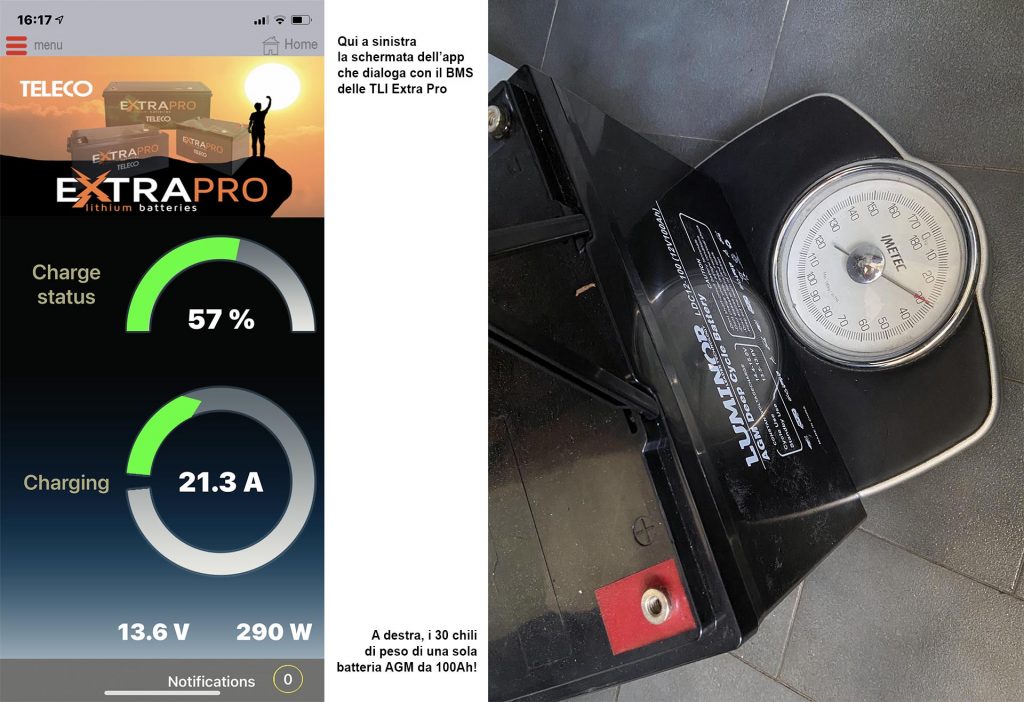

LESS WEIGHT – The fourth big advantage of lithium is weight. Our Teleco TLI Extra scores 10.5 kilograms on the scale, against the 30 of the AGM that we used as a term of comparison. Do not underestimate this aspect, as most of our vehicles travel at the limit of the maximum permissible weight, if not beyond. And if you have a dual battery configuration the difference becomes really substantial.

One battery instead of two and unchanged autonomy!

During our excursions, the Teleco battery performed exactly as promised. Since our test wanted to be a little more extreme, we replaced a double AGM accumulator with a single lithium one. And we can confirm that our average autonomy, under the same conditions of use, has not changed: with Falkor, we have always been able to work about 4 days/3 nights before entering the energy reserve. We achieved the same value with the single lithium battery, and by connecting the solar panels we extended it by one day, weather permitting. Removing over 50 kilos of weight!

We come to the last aspect of lithium batteries, which requires attention. At the moment we have done what is not optimal: we took the lead elements and put the LiFePO4 in their place. As we have seen above, in the charging phase, the best performance is obtained by reviewing the system, because the current involved and the charging curve are different. Without touching the existing one, in a system designed correctly from the start, there are no safety risks, but the efficiency of the battery certainly suffers. Our expectation is due to the fact that in the near future we want to test the new TBCM PRO 45/30/350 multicharger from Teleco, which was not yet available at the time of installation of the TLI Extra. As soon as we are able to “adopt it” we will give you our impressions of use.

The three elements to be evaluated in the existing system

In a definitive installation, there are therefore several elements to evaluate. Let’s see them one by one:

- The 220 Volt mains charger (which is often integrated into a complete control unit) should provide the specific charging curve for lithium batteries, in order to speed up the operation.

- The solar panel charge controller, like the mains charger, must have a curve suitable for lithium technology.

- Recharging from alternator, in particular with the most modern “smart alternators”, must be managed by an adequate regulator, defined in this case as DC/DC converter. For this component, it is important to check that the section of the connection cable is adequate, as lithium batteries tend to absorb all the excess energy produced by the alternator and risk putting the wiring under stress.

That’s when lithium technology becomes irresistible

For an ideal system, therefore, the expense may not be limited to the purchase and installation of the battery but rise due to the effect of replacing other components. As we have seen, deciding whether or not to switch to the new technology is a personal choice also linked to your economic availability. In our opinion, if you can afford the purchase and adaptation of the system, it is worth making the leap: for many years we will have peace of mind and the performance of the system will be at the highest levels possible today. We would make a sacrifice without a doubt if we had problems with autonomy or the need to quickly recharge the batteries.

If, on the other hand, our lead, AGM or Gel batteries have never put us in difficulty, there is no reason to make an investment of this kind, if not at the end of the useful life of our accumulators. A certain importance also goes to the life expectancy of the vehicle: if you plan to sell it in the short or medium term, it might not be worth investing in lithium technology. As a fulltimer we obviously do not have the doubt: for us the advantages are so many and clear that it makes no sense to remain anchored to lead, even if it played its part very well.

When it is (very) cold, charging can wait

In order not to forget anything, it is worth mentioning what many believe to be a negative point of lithium batteries, namely the impossibility of recharging the accumulator at temperatures below zero Celsius degrees. This is true, but it must be taken into account that the Battery Manager System (BMS, the electronics that monitors the individual cells and the battery as a whole) prevents charging from starting in these conditions, allowing it only when the safety values are reached. Furthermore, if you are using the vehicle normally, we will hardly have a temperature below zero degrees inside the cell or cabin.

You just need to be aware of this when you take the vehicle to leave: if we are parked in the cold, some time will have to pass before the charge starts. Presumably, however, the battery will not be completely discharged and will be able to deliver energy regularly with temperatures between -20 and +60 degrees.

Are you charged? But how charged are you?

To close our usage impressions, let’s add a comment that may be useful. Evaluating the actual state of charge of a battery is never easy. In lead accumulators, however, there is an indicator that is quite true: the voltage. For this reason, in the control units this is used to give an indication of the charge level.

With a little experience, you don’t even need a “translator” as a percentage: we know that a charged battery “at rest” offers about 12.7/12.8 Volts, that when it is charging it exceeds 13.5 Volts and that when drops below 12 we are close to exhaustion. With lithium batteries this indication is more difficult to assess. When they are charging, they can show even more than 14 Volts, but when they are at rest they stabilize around 13.5 Volts until they suddenly “collapse”.

Teleco TLI Extra Pro: complete information

Estimating the residual autonomy is therefore difficult. For a product like ours, which has an integrated BMS and no communication functions to the outside, the only way is to use a shunt, a device that can accurately measure how much current enters and leaves the accumulator, thus calculating the residual energy.

If you do not want to introduce additional elements into the system, you can evaluate, while remaining within the Teleco area, the TLI Extra Pro, available batteries – such as the “standard” versions – with capacities of 100, 160 and 200Ah. This range of products has a BMS with cable and Bluetooth communication functions that can communicate with a control panel with OLED display or with a smartphone app to show all the relevant parameters: voltage, current, power, status of charge and any alarms.

©2021 seimetri.it – If you want to leave a comment on this article, you can do it on our Facebook page